ALFAPAN 5+

The New Generation of Chipboard

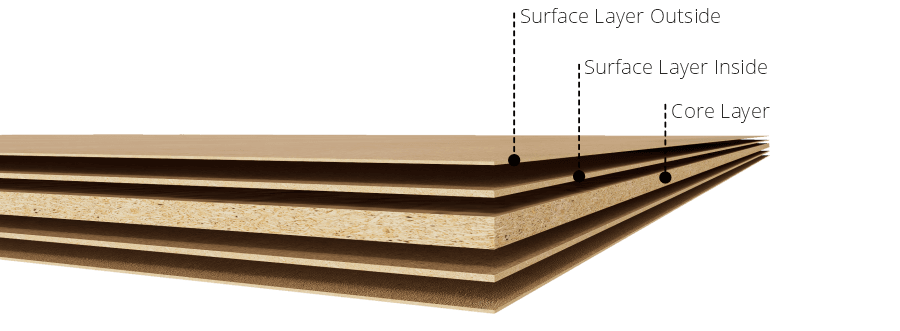

The ALFAPAN 5+ is the advanced five-layer chipboard produced in the new factory of Alfa Wood Group in Komotini.

Combines top quality raw materials, specialized distribution 5 layers and precise industrial control, to offer stamina, stability, homogeneity and perfect coating surfaceIt is the ideal choice for demanding furniture and interior decoration applications, with performance that exceeds international standards.

ALFAPAN 5+

Technical Details

- Structure: 5-layer (SLO / SLI / CL / SLI / SLO)

- Tensile (Internal Bond): >4.5 kg/cm²

- Screw holding capacity: >70 kg (socket), >90 kg (surface)

- Thickness variation: <0.10 mm

- Formaldehyde emission: E1

- Stability & machinability: high, suitable for CNC, welding, investments

Produced Dimensions

3.66 x 1.83cm

4.20 x 2.07cm

2.80 x 2.07cm

3.05 x 1.85cm

The 5-layer structure offers:

- Excellent cladding surface, with uniform density and smooth texture, ideal for cladding with melamine, veneer or other decorative materials.

- High tensile strength, thanks to the homogeneous material distribution and the transient stability of the intermediate layers.

- Excellent screw retention, both on the surface and in the chuck, ensuring robust constructions and durable mechanical strength.

- Tight and solid chocobo, without gaps, for clean cuts and stable edge banding.

- Homogeneity of mechanical properties across the entire surface of the panel, without deviations at points of tension or loading.

- Low formaldehyde content, at levels below international E1 standards, suitable for modern certified indoor applications.

- Compatibility with CNC machining and modern furniture production technologies, with stable performance in automated systems.

Presentation of Komotini Factory - Production Lines

The video shows the complete production line:

✔️ Production of ALFAPAN 5+ chipboard with five-layer technology

✔️ Grinding line with high surface accuracy

✔️ Melamine veneer unit on particleboard panels

✔️ Indoor unit decorative paper impregnation (2-stage)

✔️ Quality control and laboratory testing in the privately owned chemical plant

✔️ Storage & distribution with modern logistics infrastructure

Raw materials &

Wood Quality

- Wood: Pine, beech, poplar and pure recycled raw material

- Absence of bark, stone, metals

- Ideal granulometry per layer (thin-thick Flakers for the CL core)

- Ideal wood "recipe" for high mechanical performance

NON CARCINOGENS

raw materials

STAMINA

IN MOISTURE

STAMINA

IN TIME

STAMINA

IN THE FRICTION

STAMINA

IN ENGRAVING

easy

CLEANING

STAMINA

IN ACID

STAMINA

ON IMPACT

STAMINA

IN EXTREMES

TEMPERATURES

STAMINA

IN ENGRAVING

ALFAPAN 5+

Factory Komotini

The industrial facilities in Komotini are located on a plot of land with a total area of 297,000 sq m, with the building facilities covering 58,615 sq m. The products produced by the factory are:

- Particleboard Production

- Melamine sheet impregnation

- Veneer coated chipboard

- Coated sheets of fiberboard